Innovation needs technological vision. We accompany your digitalization process through to implementation by advising you on current technologies in an initial consultation, carrying out maturity analyses for your company and, if required, providing the necessary infrastructure so that you can test new developments without having to make large investments.

First steps

Do you want to promote AI and cyber security in your company or need support with digitalization topics? Please feel free to arrange a free* orientation meeting with us. Together we will check which measures and steps are suitable for your project.

Discover further options

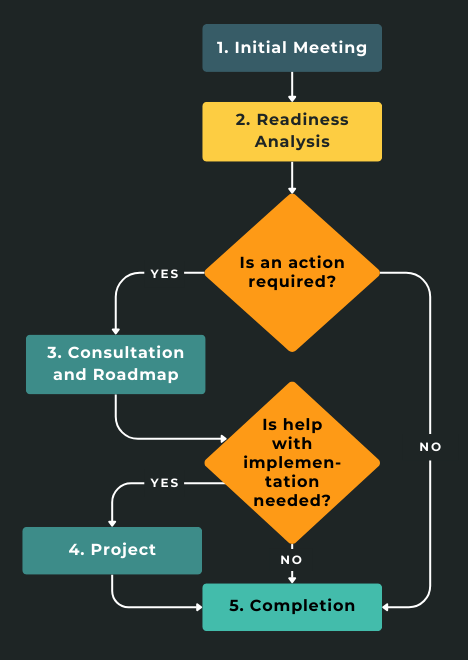

After the first meeting, in which we discuss your ideas, requirements and prerequisites for the introduction of new AI or cybersecurity technologies or your digitization issues, we carry out an analysis (Readiness Analysis) for your company or institution. We check whether and, if so, what measures can be taken to achieve your goal.

If further steps are necessary or desired, we will draw up a planning schedule with you (Roadmap) for the implementation of your project. Our Experts are at your side with their specialist knowledge if you need further support with the implementation and will accompany your innovation or digitalization process to the end.

Use cases and demonstrators

Demonstrator: AI-supported image generation for creative solutions

The use of artificial intelligence to generate and process images opens up a wide range of opportunities for companies. With our demonstrator, we showcase the impressive capabilities of the Stable Diffusion image generation AI model and illustrate how this technology can be applied in practice.

Imagine being able to use image generation AI models in the initial design phase, whether for products, interior design or other creative projects. You can use sketches or photorealistic representations to impress customers and bring shared ideas to life. Marketing materials such as logos, advertising or personalized images can also be created efficiently using this technology.

Our demonstrator allows you to experience this pioneering software up close in action. Step by step, we guide you through the image generation process. We show you how easy it is to use "prompts" - short text descriptions - alone or in combination with sketches to have Stable Diffusion generate impressive images.

Take the opportunity to get to know this innovative solution in person. Experience for yourself how AI-based image generation can revolutionize your projects and send us a request to receive an online demonstration of Stable-Diffusion.

Services

Demonstrator: Central production control

Many medium-sized companies in the manufacturing sector are organized according to the workshop production principle. In this context, machine allocation and sequence formation represent a complex optimization problem (Flexible Job Shop Scheduling Problem). The demonstrator of the Mittelstand-Digital Zentrums Hannover illustrates how quantum-inspired digital annealing can help to solve this challenge in the shortest possible time and with high quality. Via a user interface, visitors are first shown the simple handling of the optimization tool and an optimization is carried out jointly. Afterwards, a material flow simulation visualizes the result using the example of a Tesa-Roller production line. The direct comparison with widely used allocation and sequence rules immediately shows the productivity potential.

Demonstrator: Learning Visual Control System

The demonstration factory of Mittelstand-Digital Zentrums Hannover shows intelligent digitalization solutions from comissioning to manufacturing and assembly to quality control. Visitors can experience digitalization solutions by experiencing first hand the production of a pen in batch size 1. One of the stations - consisting of a lathe and a bar storage system - shows the manufacturing process of the pen's grips made of aluminum bars. Here, an AI-based solution has been implemented to monitor the supply of material by the bar feeder. Workers receive a warning message as soon as a foreign object is detected in the system. In this way, unplanned machine downtime can be avoided.

A learning visual control system was built for monitoring, which provides as output information about the state of the warehouse and the location of the objects in it. The developed deep learning model is able to locate and describe the objects in the aluminum rod bearing. All calculated information (type and position of the object) is visualized and integrated into an image streamed from the camera.

Demonstrator: Quality assurance in the digital transformation

Quality checks along the entire production process can reduce costs, simplify workflows, and increase product and process quality. For this, automated, data-rich, and cross-process quality assurance is a suitable tool.

But not every company is already fully automated and has continuous machine data evaluation in real time. In this case, it may be a matter of implementing partial solutions. An example of such a partial solution can be found in the demonstration factory of the Mittelstand-Digital Zentrums Hannover: Here, the quality inspection was implemented with the help of a a collaborative robot, sensors and artificial intelligence. The quality inspection can be flexibly integrated into different process cycles.

Partners

The Mittelstand-Digital Zentrum Hannover is part of the Mittelstand-Digital network. The funding priority offers small and medium-sized enterprises comprehensive support for digitization with the Mittelstand-Digital Centers, the Initiative for IT Security in Business and Digital Jetzt. They benefit from concrete practical examples and tailored, vendor-neutral offers.

Maturity level analysis

Services

The digital needs analysis provides skilled crafts businesses with information on the degree of digitalization in your company and on further development potential.

Demonstrator management

Services

The Mittelstand-Digital competence centers have set up an information platform for their demonstrators. In this way, the centers make digitalization a tangible experience and use practical application examples to demonstrate where medium-sized companies can start in their own businesses. The new online platform provides an overview of what can be tried out on site or digitally.

Consulting and knowledge transfer

Services

For many companies, especially those that are medium-sized or small, it is often difficult to navigate the plethora of existing AI technologies. The L3S Research Center offers a wide range of consulting services ranging from data analytics to image recognition to assist companies in selecting and deploying the appropriate technologies.

Services

Basic research is the basis of many innovations. Start-ups represent an opportunity to create added value for society and the economy by commercializing these innovations. Therefore, CISPA supports scientists in the transfer of research into new business models and builds up a venture ecosystem. The CISPA incubator supports this process with a wide range of workshops and consulting services.

A team of business development managers and technical consultants therefore supports prospective founders in the idea and start-up phase. This support includes the conception and realization of new business models in the area of IT security:

- Staffing of venture teams and search for co-founders

- Coaching regarding idea evaluation, product development, business model conception and market entry

- Moderated exchange with internationally renowned researchers in idea generation and product development

- Fundraising support from public funding programs and private venture capitalists

- Facilitated market entry through an international network of industrial research partners

Our services are free of charge for SMEs, start-ups and public institutions thanks to the financial support DAISEC receives from the European Union.